The Sea Flyer

The Future

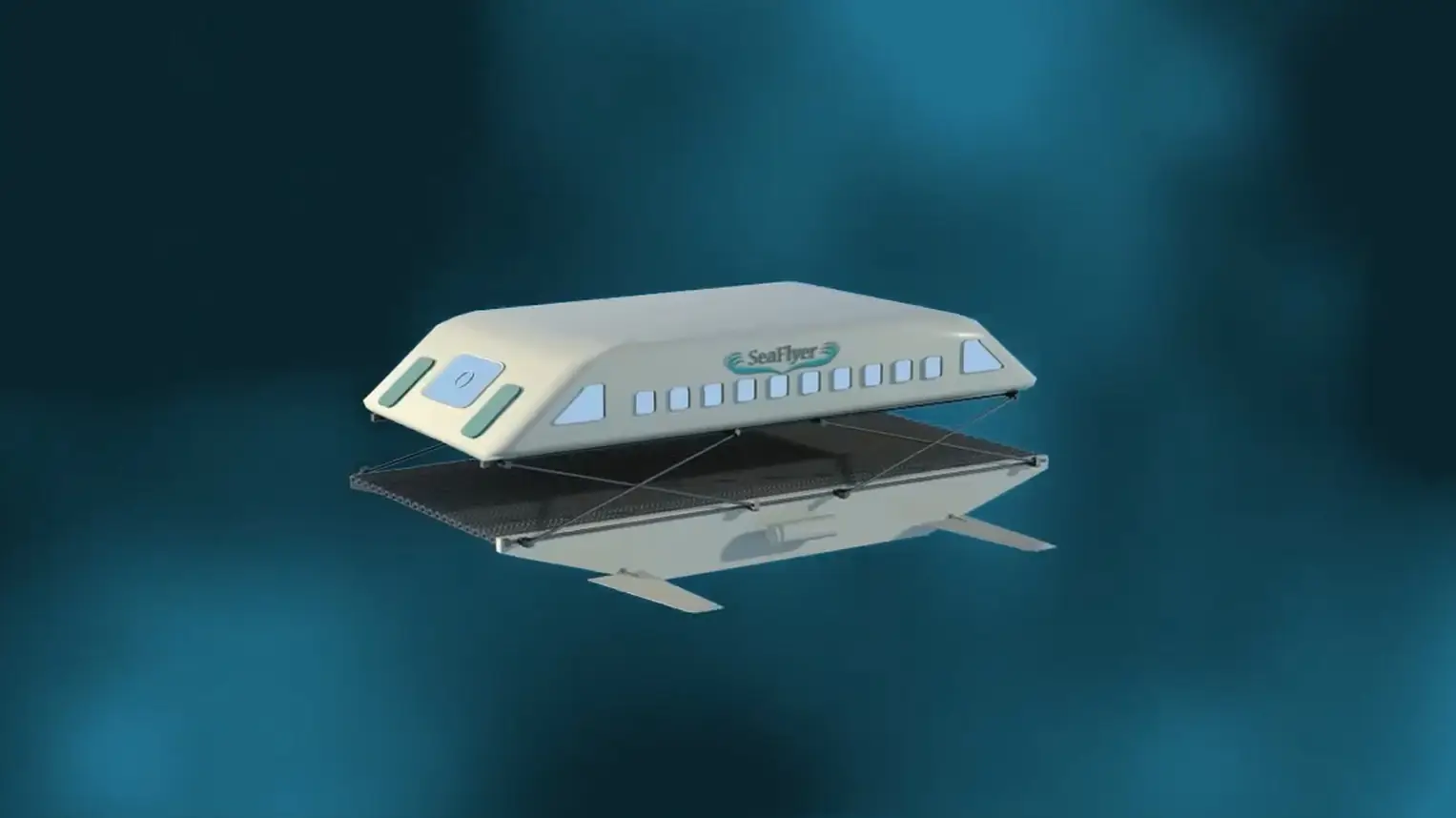

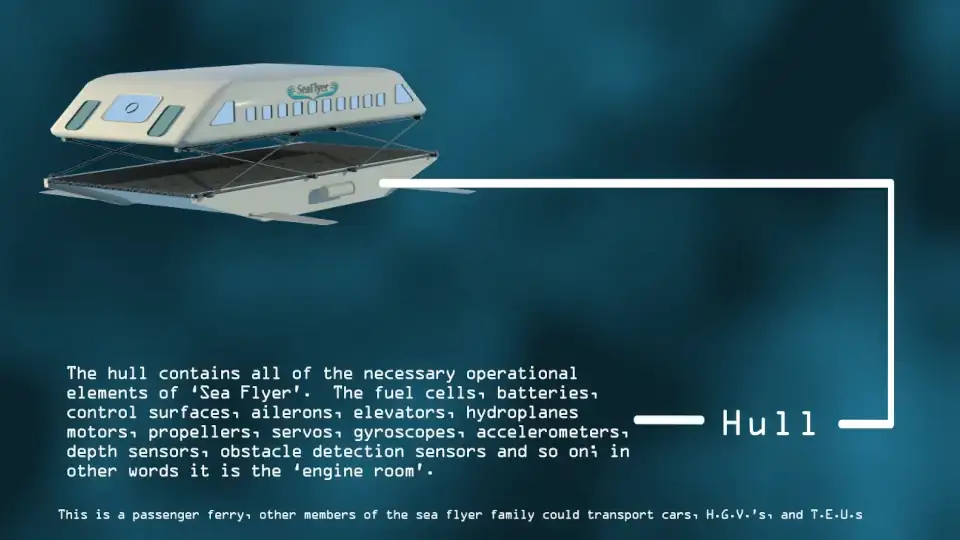

The ‘Sea Flyer’ family is a scalable form of marine vessel. In other words it can be used as a towable SUV (sports utility vessel), a small enclosed 9 passenger carrier, (Sea Taxi), a fast 100 to 250 passenger ferry, (Sea Bus), a fast passenger and car carrier, (Sea Flyer), a container carrier, (Sea TEU), and so on. As the vessels get larger and are no longer carrying passengers the cargo could go in the hull, under the surface of the sea and only the crew, crew’s quarters, controls, GPS and weather collecting systems are in the cabin. How this concept will be used is more or less at the performer’s pleasure. Having got this far there are at least three more patents in the making; to improve efficiency, economy, range and speed.

Think about this, how things have changed. 30 or so years ago a well-known personality thrashed his way across the Atlantic to claim the Blue Riband for the fastest crossing.

In the future, the same person using a ‘Sea Dream’ luxury ultra-yacht could take his family and friends from Plymouth UK to Plymouth USA in comfort and style in 65 hours instead of the 65 days that the Pilgrim Fathers took.

2020 was the 400th anniversary of the initial crossing in 1620. That is what is on offer and how things have changed.